- Polypropylene PPR Pipes

- Fiber Glass Three-Layer PPRC Fibre Pipes

- Polypropylene Socket Pipes for Internal Sewage

- Drip Irrigation Pipes

- Pipes PE 100

- Welded Fittings for PE 100 Pipes

- PPRC fittings

- Corrugated Pipes

- Single-Layer Corrugated Pipes

- Double-Layer Corrugated Pipes

- Double-Layer Corrugated Polypropylene Pipes

- Fittings for Corrugated Pipes

- Concentric and Eccentric Crossovers

- Spirally Rolled High-Pressure and Low-Pressure Pipes with a large diameter

- Cast Fittings for PE 100 Pipes

- PPH Sewage Fittings

Concentric and Eccentric Crossovers

General information

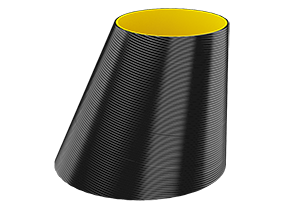

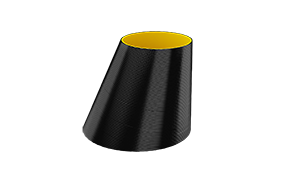

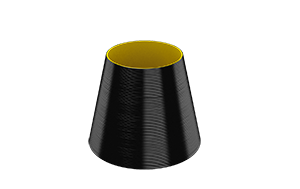

The crossovers are produced in two forms – concentric and eccentric. In concentric crossovers the centres of diameters of inlet and outlet pipes is located on one axis of symmetry while in eccentric crossovers these centres are located on two parallel axes against each other.

The crossovers with different sizes based on the corrugated pipes (SN8) are produced in the Plant of Polymeric Products for connecting pipes of different diameter in unpressurized sewage pipelines. Being coupling elements of pipelines the crossovers are in various diameters in the ends of pipelines that is when changing from one diameter to another, as well as when it is necessary to increase or decrease the transported liquid flow rate they are mounted in the pipelines. In other words, by using such details it is possible to direct the loadings in pipelines to various directions or split them into branches. It is possible to increase pressure by narrowing the pipe while to decrease by expanding it.

The crossovers are produced in two forms – concentric and eccentric. In concentric crossovers the centres of diameters of inlet and outlet pipes is located on one axis of symmetry while in eccentric crossovers these centres are located on two parallel axes against each other. For this reason, the form of concentric crossovers is like a cut cone and mainly, these crossovers are installed in vertical pipelines for mixing the different substances. And since eccentric crossovers are like a cut cone being on axes with parallel seats they are often used in connections of horizontal pipelines. Moreover, when using eccentric crossovers the sediments of the transported substance are eliminated. It is easy to clean them during repair, current maintenances and in case of other problems occurred.

It should be noted that there is a big demand on these items as they are very durable and made of firm materials. These crossovers are marketed after passing comprehensive test. In addition, they have several following advantages:

- First, inside and outside diameters of crossovers mounted in pipelines, as well as the sizes of endpoints of them overlap with high accuracy;

- Second, material of crossovers has quality structure, impact resistance and high weldability.

SEMIFINISHED MATERIAL FOR ECCENTRIC CROSSOVER

| Dd1-Dd2, mm | Xd1-Xd2, mm | Height H, mm | Thickness, a, mm |

500/400 500/300 400/300 300/250 300/200 300/150 250/200 250/150 200/150 | 550/450 550/350 450/350 340/290 340/240 340/190 290/240 290/190 240/190 | 230 460 230 126,7 253,3 380 126,7 253,3 126,7 | 25 25 25 20 20 20 20 20 20 |

SEMIFINISHED MATERIAL FOR CONCENTRIC CROSSOVER

| Dd1-Dd2, mm | Xd1-Xd2, mm | Height H, mm | Thickness, a, mm |

500/400 500/300 400/300 300/250 300/200 300/150 250/200 250/150 200/150 | 550/450 550/350 450/350 340/290 340/240 340/190 290/240 290/190 240/190 | 230 460 230 126,7 253,3 380 126,7 253,3 126,7 | 25 25 25 20 20 20 20 20 20 |

CONCENTRIC SMOOTH CROSSOVER

- Material: PPH

- Diameter, d1-d2 (mm):

| 200/150 | ||||||

| 250/150 | ||||||

| 250/200 | ||||||

| 300/150 | 300/200 | 300/250 | ||||

| 400/150 | 400/200 | 400/250 | 400/300 | |||

| 500/150 | 500/200 | 500/250 | 500/300 | 500/400 | ||

| 600/150 | 600/200 | 600/250 | 600/300 | 600/400 | 600/500 | |

| 800/150 | 800/200 | 800/250 | 800/300 | 800/400 | 800/500 | 800/600 |

ECCENTRIC SMOOTH CROSSOVER

- Material: PPH

- Diameter, d1-d2 (mm):

| 200/150 | ||||||

| 250/150 | ||||||

| 250/200 | ||||||

| 300/150 | 300/200 | 300/250 | ||||

| 400/150 | 400/200 | 400/250 | 400/300 | |||

| 500/150 | 500/200 | 500/250 | 500/300 | 500/400 | ||

| 600/150 | 600/200 | 600/250 | 600/300 | 600/400 | 600/500 | |

| 800/150 | 800/200 | 800/250 | 800/300 | 800/400 | 800/500 | 800/600 |