- Polypropylene PPR Pipes

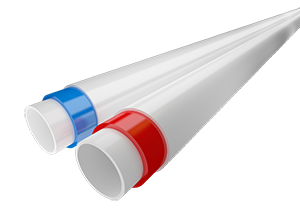

- Fiber Glass Three-Layer PPRC Fibre Pipes

- Polypropylene Socket Pipes for Internal Sewage

- Drip Irrigation Pipes

- Pipes PE 100

- Welded Fittings for PE 100 Pipes

- PPRC fittings

- Corrugated Pipes

- Single-Layer Corrugated Pipes

- Double-Layer Corrugated Pipes

- Double-Layer Corrugated Polypropylene Pipes

- Fittings for Corrugated Pipes

- Concentric and Eccentric Crossovers

- Spirally Rolled High-Pressure and Low-Pressure Pipes with a large diameter

- Cast Fittings for PE 100 Pipes

- PPH Sewage Fittings

Fiber Glass Three-Layer PPRC Fibre Pipes

General information

Due to their advantages such as lightweight and smoothness, slippery and bright internal surface and easy installation these hygienic PPR fibre pipes are used in cold and hot water facilities inside the building without any impurities and corrosion.

One of the most important processes in plastic mass processing industry is obtaining “Random polypropylene (PPR)” and applying it in the industry. The pipes that are made of this raw material are widely used in modern life.

Due to their advantages such as lightweight and smoothness, slippery and bright internal surface and easy installation these hygienic PPR fibre pipes are used in cold and hot water facilities inside the building without any impurities and corrosion.

- The most important feature of feedstock of plastic pipes is its high resistance to heat and chemical effects. Due to this resistance PPR pipes are successfully used in cold and hot water facilities. PPR pipes do not form any colour, taste and odour. Their universal heating capability is of special importance. “Random polypropylene” based pipes are operated in temperatures up to +95 °C. Elasticity of the pipes prevents crack formation, when water is frozen inside.

- In production of fiber glass pipes the Polymeric Products Plant uses its high quality polypropylene products fully meeting international standards. The pipes are produced in equipment made by Mikrosan, Turkey. Plant produces PPR based white and grey fibre (with glass fibre compound) pipes.

- We offer our clients high quality and cost-effective pipes.

- Main advantages:

- quality: European made raw materials meet the requirement of DIN, TSE, ISO 9002 standards;

- reliability: the systems assembled from these pipes have high tightness;

- pipe life cycle: life cycle is above 50 years for cold and hot water and this period may change depending on working temperature;

- corrosion and chemical resistance: these pipes are resistant to corrosion and aggressive environment, their transmission capacity is high due to smooth inner surface;

- environmentally cleanness: polypropylene does not react with water, therefore does not add any taste to the water. Since their inner surface is slippery organic and inorganic sediments and impurities are not observed;

- durability: fiber glass material forming middle layer prevents pipe bending due to linear expansion in high temperatures and significantly increases the pressure resistance;

- usage: Resistance to hot water flows at +95 ˚C temperature (pipe should be insulated by taking into account the fluid freezing degree). Diameter does not narrows in the welds. Excellent welding. 70 % savings in installation and no losses occur during mounting. Heat and sound insulation. Inflame-resistant;

- Technical characteristics:

- Type of pipe: outer and inner layer PPR, middle layer consists of fiberglass PPR compound.

- Colour: white and grey.

- Length: 4 m (other lengths may be provided at request).

- Linear expansion factor: 0.035 mm/m °C.

- Areas of application: air-conditioner and heating water, technical and potable water supply etc.

- Parameters of fiberglass pipes

o Outside diameter, D mm | o Diameter deviation, mm | o Wall thickness, S mm | o Wall thickness deviation, mm |

o 16 o 20 o 25 o 32 o 40 o 50 o 63 o 75 | o +0.3 o +0.3 o +0.3 o +0.3 o +0.4 o +0.5 o +0.6 o +0.7 | o 2.7 o 3.4 o 4.2 o 5.4 o 6.7 o 8.3 o 10.5 o 12.5 | o +0.3 o +0.4 o +0.5 o +0.6 o +0.7 o +0.8 o +1.0 o +1.2 |