ОКЛм-Т

General information

A-D(ZN)(SR)T2Y / A-D(BN)(SR)T2Y (ОКЛмТ-T) type fiber optic cable with a central tube armored with laminated corrugated steel tape, single-layer-coated, with (eight-stranded) suspension rope for suspension on power line pylons

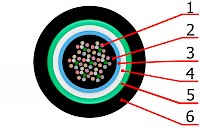

Cable Construction Design

The bearing member is placed in parallel to the twisted conductor. The bearing member can consist of a steel rope or a dielectric-based strength member (fiberglass rod). Optical fibers are freely placed inside the tube and interstice is filled with a hydrophobic gel. The cable core is sheathed with aramid yarns or fibers glass yarns and laminated corrugated steel tape armor, the bearing member is sheathed with a high-density polyethylene outer jacket.

- Optical fiber

- Hydrophobic gel

- PBT tube

- Aramid yarns (ZN) or fiberglass yarns (BN)

- Corrugated steel tape armor

- Outer jacket

Color Identification of Fibers and Tubes (IEC 60304)

|

On customer’s request, the color identification of fibers and tubes can be changed. In the case that number of fibers exceeds 12, the identification is conducted by circular coloring.

Number of fibers | 2-12 | ||||

Number of tubes | 1 |

Temperature range during operation | -40 °C.....+60 ºC |

Temperature range during installation | -10 °C.....+50 ºC |

Temperature range during transportation and storage | -50 ºC......+50 ºC |

Minimum bending radius | 20xD |

Tensile strength (IEC 60794-1-2 E1) | 1 ÷ 3.5 kN |

Crush strength (IEC 60794-1-2 E3) | 3.0 kN/100 mm (min) |

| Temperature range of operation | -40°C.....+60ºC |

| Temperature range of installation | -10°C.....+50ºC |

| Temperature range of transportation and storage | -50ºC......+50ºC |

| Minimum bending radius | 20xD |

| Tensile strength (IEC 60794-1-2 E1) | 1 ÷ 3.5 kN |

| Crush strength (IEC 60794-1-2 E3) | 3.0 kN/100 mm (min) |