- Polypropylene PPR Pipes

- Fiber Glass Three-Layer PPRC Fibre Pipes

- Polypropylene Socket Pipes for Internal Sewage

- Drip Irrigation Pipes

- Pipes PE 100

- Welded Fittings for PE 100 Pipes

- PPRC fittings

- Corrugated Pipes

- Single-Layer Corrugated Pipes

- Double-Layer Corrugated Pipes

- Double-Layer Corrugated Polypropylene Pipes

- Fittings for Corrugated Pipes

- Concentric and Eccentric Crossovers

- Spirally Rolled High-Pressure and Low-Pressure Pipes with a large diameter

- Cast Fittings for PE 100 Pipes

- PPH Sewage Fittings

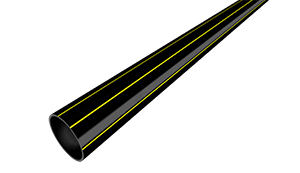

Pipes PE 100

General information

Production of PE 100-based polyethylene pipes is considered as the beginning of a new stage in pipe production. These pipes are considered the most modern polyethylene (PE) pipes that are known for their high pressure resistance.

Production of PE 100-based polyethylene pipes is considered as the beginning of the new stage in pipe production. These pipes are considered the most modern polyethylene (PE) pipes that are known for their high pressure resistance. These pipes have less wall thickness and more advantageous mechanical properties compared to other brand (PE 63. PE 80) pipes. Polymeric Products Plant of Sumgait Technologies Park is capable to produce pressure-resistant pipes PE100 with diameter of 16-1200 mm and at 6.3-25 atmospheric pressure.

Area of application:

- Underground and surface potable water networks with technical destination.

- Sea water discharge systems.

- Water drainage system.

- Field irrigation systems.

- Oil fields.

- Chemical and petrochemical industry.

- Construction of buildings and industry facilities.

- Mining industry.

- Laying main and local natural gas lines.

Advantages:

- durability. with minimum 50 years of guarantee РЕ 100 pipes may be operated for 100 years;

- high impact resistance, crack resistance;

- high chemical resistance;

- sun rays resistance;

- production in the form of roll and in standard size;

- smooth inner surface that minimizes scale accumulation during water flow;

- suitable for usage in seismically active areas ;

- freeze resistance;

- high pressure resistance (PN4÷PN20) that allows production for broad pressure range depending on pipe ordering;

Size limit of pipes produced under normal pressure

- DN – rated pipe diameter, (mm)

- s – pipe wall thickness, (mm)

- SDR – standard dimension ratio

- M – one meter weight (kg/m)

# | Diameter, (mm) | Wall thickness (mm) | SDR | Pressure resistance (atm.) |

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 | 16 16 20 20 20 25 25 25 25 32 32 32 32 40 40 40 40 40 50 50 50 50 50 63 63 63 63 63 75 75 75 75 90 90 90 90 110 110 110 110 125 125 125 125 140 140 140 140 140 160 160 160 160 160 180 180 180 180 180 200 200 200 200 200 225 225 225 225 225 250 250 250 250 250 280 280 280 280 280 315 315 315 315 315 355 355 355 355 400 400 400 400 400 400 450 450 450 450 450 500 500 500 500 500 560 560 560 560 560 630 630 630 630 630 710 710 710 710 710 800 800 900 900 1000 1000 1200 1200 | 1.8 2.2 1.8 1.9 2.3 1.8 1.9 2.3 2.8 2.0 2.4 3.0 3.6 1.9 2.4 3.0 3.7 4.5 2.4 3.0 3.7 4.6 5.6 3.0 3.8 4.7 5.8 7.1 2.9 4.5 5.6 6.8 3.5 5.4 6.7 8.2 4.2 6.6 8.1 10.0 4.8 7.4 9.2 11.4 5.4 6.7 8.3 10.3 12.7 6.2 7.7 9.5 11.8 14.6 6.9 8.6 10.7 13.3 16.4 7.7 9.6 11.9 14.7 18.2 8.6 10.8 13.4 16.6 20.5 9.6 11.9 14.8 18.4 22.7 10.7 13.4 16.6 20.6 25.4 12.1 15.0 18.7 23.2 28.6 13.6 16.9 21.1 26.1 32.2 15.3 19.1 23.7 29.4 36.3 17.2 21.5 26.7 33.1 40.9 19.1 23.9 29.7 36.6 45.4 21.4 26.7 33.2 41.2 50.8 24.1 30.0 37.4 46.2 57.2 27.2 33.9 42.1 52.2 64.5 30.6 47.4 34.4 53.3 38.2 59.3 45.9 70.5 | 9.0 7.4 13.6 11.0 9.0 17.0 13.6 11.0 9.0 17.6 13.6 11.0 9.0 21.0 17.0 13.6 11.0 9.0 21.0 17.0 13.6 11.0 9.0 21.0 17.0 13.6 11.0 9.0 9.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21.0 17.0 13.6 11.0 26.0 21 17.0 13.6 11 26 17 26 17 26 17 26 17 | 20.0 25.0 12.5 16.0 20.0 10.0 10.0 16.0 20.0 9.5 12.5 16.0 20.0 8.0 10.0 12.5 16.0 20.0 8.0 10.0 12.5 16.0 20.0 8.0 10.0 12.5 16.0 20.0 20.0 10.0 12.5 16.0 6.3 10.0 12.5 16.0 6.3 10.0 12.5 16.0 6.3 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 8.0 10.0 12.5 16.0 6.3 10.0 6.3 10 6.3 10.0 6.3 10.0 |