Plant for the Production of Aluminium and Copper Profiles

General information

The Aluminum and Copper Profile Production Plant (STP) was commissioned in 2014. The plant is engaged in the production of aluminum profiles and powder coatings as well as the smelting of aluminum and copper.

The Aluminum and Copper Profile Production Plant (STP) was commissioned in 2014. The plant is engaged in the production of aluminum profiles and powder coatings, as well as the smelting of aluminum and copper. The company employs specialists trained at such specialized enterprises as HANKELL Rus (Russia) and TAİSS (Italy).

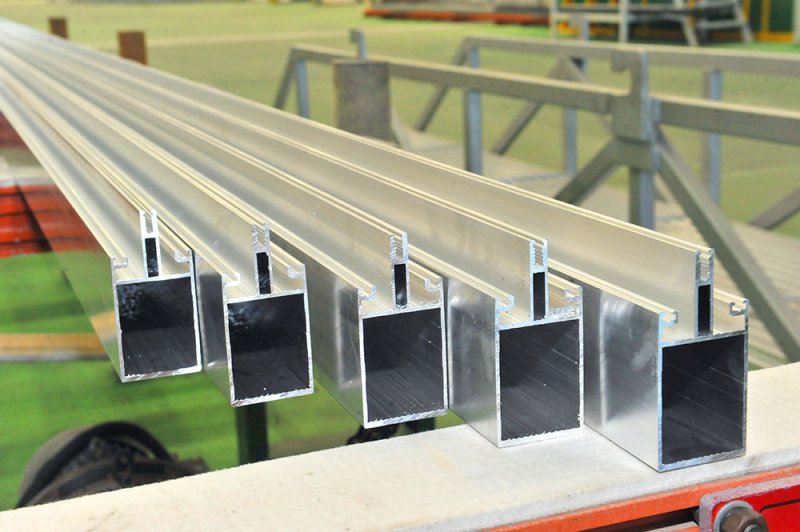

In the aluminum profiles production zone, profiles and strips of various widths and configurations are manufactured by pressing, while in the smelting and pre-fabrication zone, aluminum feedstock is processed.

The monthly design capacity of the powder coating area is 240 tons. This was commissioned in 2015. The used equipment belongs to the Turkish company BOTERSAN.

In the aluminum smelting and pre-production zone, raw materials are smelted and sent to the profile production area. The furnaces have an annual capacity of 30,000 tons. Blanks of models AA6060, 6061, 6063 and AD-31, with 4 diameters 152 mm, 178 mm, 203 mm and 254 mm, are produced here, with their composition and mechanical properties set in accordance with the EN 573-3 standard. One of the main factors distinguishing our product from those produced at other enterprises is the compliance of both the chemical and physical characteristics of these blanks with the requirements of the mentioned standards. This is also confirmed by the results of many tests. This is due to the high quality of the melting furnace, molding machine and homogenization complex, the skills of our technical specialists and the full compliance with the technological regulation requirements.

The Aluminum and Copper Profile Production Plant produces profiles for facades, aluminum billets of length 6 meters and diameters 152 mm, 178 mm, 203 mm and 254 mm, hot and cold series profiles, window systems, aluminium electrical bus bars used in high-voltage rooms, standard profiles and profiles according to the client’s specifications.

The quality management system of the enterprise is certified in accordance with the requirements of ISO 9001. The production process uses raw materials and equipment that meet international standards.