- Polypropylene PPR Pipes

- Fiber Glass Three-Layer PPRC Fibre Pipes

- Polypropylene Socket Pipes for Internal Sewage

- Drip Irrigation Pipes

- Pipes PE 100

- Welded Fittings for PE 100 Pipes

- PPRC fittings

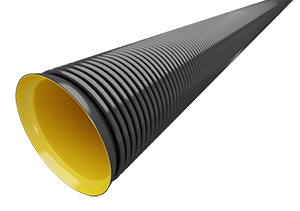

- Corrugated Pipes

- Single-Layer Corrugated Pipes

- Double-Layer Corrugated Pipes

- Double-Layer Corrugated Polypropylene Pipes

- Fittings for Corrugated Pipes

- Concentric and Eccentric Crossovers

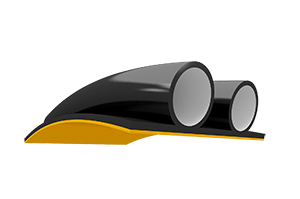

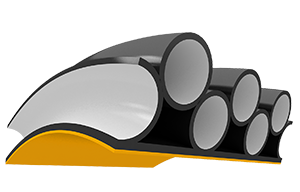

- Spirally Rolled High-Pressure and Low-Pressure Pipes with a large diameter

- Cast Fittings for PE 100 Pipes

- PPH Sewage Fittings

Spirally Rolled High-Pressure and Low-Pressure Pipes with a large diameter

General information

The Polymeric Products Plant manufactures the spirally rolled high-pressure and low pressure-pipes with a large diameter with the help of the latest technology of a well-known German company.

The Polymeric Products Plant manufactures the spirally rolled high-pressure and low pressure-pipes with a large diameter with the help of the latest technology of a well-known German company. These pipes are obtained by rolling the profile coming from extruder by the method of extrusion to the steel mold.

High and low pressure, large diameter profiled and non-profiled spirally rolled pipes manufactured in PPP can be used in many areas:

- rain and groundwater discharge;

- transmissions over water basins;

- sewage systems;

- in construction of wells, mines, reservoirs, pumping stations and underground bridges.

The following thermoplastic polymers are used for the production of these high and low pressure large diameter pipes:

- Polyethylene (PE 100);

- Homogeneous polypropylene (PP-H).

Length of pipes:

The calculated standard length of these pipes is L = 6 meters. This length facilitates the assembly, storage and transportation of pipes. PPP has the ability to produce pipes for specific purposes at lengths from 1 to 6 meters.

The plant has the ability to produce pipes with inside diameter of DN 800-3500 mm. The nominal diameter of the pipes corresponds to the inside diameter.

Structure of the walls (rolling with profile) allows the pipes to withstand higher static pressure. This structure depends on the type of profile.

PR profiles:

These types of profiles have a smooth internal and profiled outer surface. Profiles on the outside surface are wrapped by maintaining certain interval. It is possible to achieve high ring strength with small weight.

OP profiles:

These types of profiles have a smooth internal and profiled outer surface. Profiles on the outside surface are wrapped by maintaining certain interval. It is possible to achieve high ring strength with small weight.